wire edm machine is an electro process

The wire cut EDM is also known as wire electrical discharge machining and wire cutting. A Brief Bit of EDM History.

Line Diagram Of Wire Cut Edm Process Download Scientific Diagram

Essentially it is used to cut thick plates and to manufacture dies tools punches from tough metals.

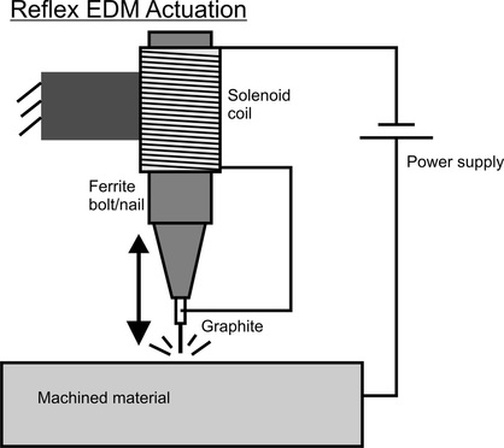

. EDM removes material by discharging an electrical current normally stored in a capacitor bank across a small gap between the tool cathode and the workpiece anode typically in the order of 50 volts10amps. With the first functioning EDM machines being developed in the war-torn Soviet Union by physicist brothers the Lazarenkos in 1943 Wire EDM was not far behind. In wire EDM the electrode is a wire and is fed through an upper and lower diamond guide.

The wire diameters usually range from 005 to 30 mm. The wire itself does not actually touch the metal to be cut. How to Thrive in Adversity.

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. The process is very common in manufacturing of injection molds. Application of EDM The EDM process has the ability to machine hard difficult-to-machine materials.

Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes separated by a dielectric liquid. He noticed that electrical discharges had removed material from the electrodes in his experiments. The wire is slowly fed through the material and the electrical discharges actually cut the workpiece.

The dielectric liquid in this case is usually deionized water. It is suitable for thermoelectric phenomena. This process allows the wire to cut through metal by the use of heat from electrical sparks.

You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always harder than the work-piece. Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks while preventing rust. When a discharge occurs between the electrodewire and the workpiece heat energy is generated on the workpiece.

People Process and Principle. The Right Machine Tool for the Right Job The price of a wire EDM machine is nothing compared to the cost of wire over the life of the machine says Tom Frick owner of Intricate EDM in Columbia Pennsylvania. Wire EDM is the most precise cutting process by the help of wire EDM we can get up to two Micron of precisionI hope you will lik.

In the 1940s two Soviet researchers the Lazarenkos developed a. Sometimes referred to as wire erosion or spark EDM wire EDM is a popular process. Sometimes referred to as wire erosion or spark EDM wire EDM is a popular process.

Wire cut electrical discharge machining WEDM is one of the most emerging non conventional manufacturing process for machining materials which are hard to machine and intricate shapes which are not possible with conventional machining methods. One company with a perspective on how these processes compare is Makino Mason Ohio a builder offering machining centers and EDM machines both. Here the thin wire acts as the electrode.

Wire electrical discharge machine. Billy Grobe is diemold operations manager for this builder and he often advises customers as to which metal removal process makes sense for their work. EDM Electro Erosion is a machining process that uses a discharge electrode EDM electrode with a specific geometry to burn the geometry of the electrode on a metal conductive part.

Wire EDM is suitable for the machining process which requires low residue stress as it does not require a higher. Wire EDM machining is an electro thermal process which utilizes a thin metal wire in a bath of with de-ionized water which is used to conduct electricity. An electrical discharge produces heat and sparks which cut the metal and prevents oxidization.

Special brass wires are typically used. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges sparks. It involves the use of a brass wire or thin copper to cut the workpiece.

Wire control is carried out by computer numerical control which programs the path of the wire. This is also known as electro-discharge erosion. This is a wire EDM machine.

Also the cutting tool applies the force to remove the material from the work-piece during machining. The electrode is used only once and is discarded after it is used. Wire EDM is a non-conventional machining process which is based on the principle of electrical discharge machining EDM.

EDM works by creating an electrical charge that emits sparks. Wire EDM machining Electrical Discharge Machining is an electro thermal production process in which a thin single-strand metal wire in conjunction with de-ionized water used to conduct electricity allows the wire to cut through metal by the use of heat from electrical sparks. The electrical discharge machining EDM process as we know it today started with the observations of Joseph Preistly in 1770.

Wire EDM In wire EDM a very thin wire serves as the electrode. Due to the inherent properties of the process wire EDM can easily machine complex parts and. The Wire EDM process is a subtractive manufacturing process.

It is often used for the production of metal parts with complex geometry. The process can be as simple as using a small diameter metal tube to cut a precise hole in a metal block to using a carved graphite block to machine a. The Electro Erosion process is often used in the production of blanking and casting dies.

It is suitable for thermoelectric phenomena. Wire is the single highest expense in operating a wire EDM. A non-conventional process though hardly a new one wire EDM works on parts resistant to conventional machining processes but only if these parts are electrically conductive.

The Electrical Discharge Machining EDM is an unconventional. Wire EDM Electrical Discharge Machining is an electro thermal manufacturing process that uses an electrically charged thin metal wire and deionized water to mill or cut conductive materials. Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges.

However EDM technology has gotten better too. Wire EDM Electrical Discharge Machining is an electro thermal manufacturing process that uses an electrically charged thin metal wire and deionized water to mill or cut conductive materials. Usually they are non-ferrous and.

Wire EDM is usually performed in a bath of water. The term EDM stands for Electrical Discharge Machining. EDM - Electrical Discharge Machining is a way of cutting metal using electricity Similar to a plasma cutter except under water.

Wire Electric Discharge Machining Wire Edm Youtube

Wire Cut Edm Process 2 Download Scientific Diagram

Wire Edm Find Suppliers Processes Material

What Is Wire Edm Electrical Discharge Machining Xact

Schematic Diagram Of Ezeecutplus Wire Edm Download Scientific Diagram

Mas S62 Final Notes Bengineering

Schematic Diagram Of Wire Edm Machine Download Scientific Diagram

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Mas 865 How To Make Something That Makes Almost Anything

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Analysis And Optimization Of Wire Electro Discharge Machining Process Parameters For The Efficient Cutting Of Aluminum 5454 Alloy Sciencedirect

Wire Edm Find Suppliers Processes Material

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Wire Cut Electro Discharge Machining Process Working Animation Video Explained With Setup Diagram Youtube

What Is Wire Edm A Guide To Wire Electrical Discharge Machining

What Is Wire Edm Electrical Discharge Machining Xact

Wire Edm Introduction As We Build Our Knowledge Database We By Factorem Medium

Block Diagram Of Wire Edm Machine Source Technological Manual Of Download Scientific Diagram